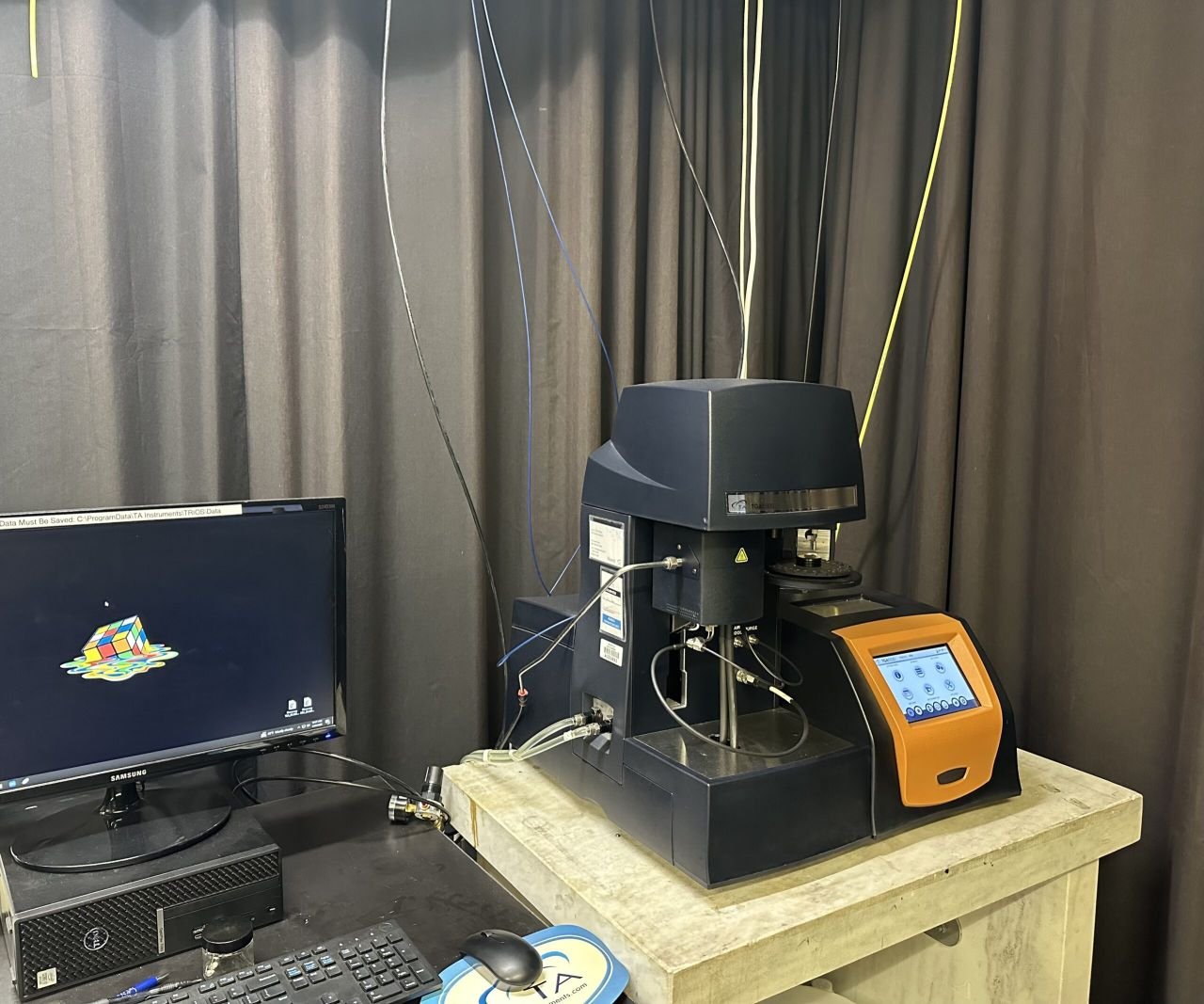

Thermogravimetric Analysis (TGA)

Thermogravimetric Analysis (TGA) is a vital analytical technique used to assess the thermal stability and composition of materials by monitoring weight changes under controlled temperature conditions. At CMG, we specialize in TGA testing to support quality control, material development, and failure analysis for rubber and polymer products.

Applications of TGA in Rubber and Polymer Testing

- Compositional Analysis: TGA helps determine the proportions of components such as polymers, fillers, plasticizers, and other additives in rubber compounds. By heating the sample and observing weight losses at different temperature ranges, it’s possible to quantify these constituents accurately.

- Thermal Stability Assessment: By subjecting materials to increasing temperatures, TGA evaluates their thermal degradation behavior. This information is crucial for predicting material performance under thermal stress.

Relevant Standards for TGA

- ASTM D6370: This standard outlines the procedure for compositional analysis of rubber using TGA. It specifies methods to determine the amounts of organics (oil, polymer), carbon black, and ash (filler) in a rubber compound.

- ASTM E1131: This standard provides guidelines for compositional analysis by thermogravimetry, applicable to various materials, including polymers. It is intended for use in quality control, material screening, and related problem-solving where a compositional analysis is desired.

TGA Testing Process

A typical TGA analysis involves heating a small sample (usually around 5-20 mg) in a controlled atmosphere, such as nitrogen or air, at a predetermined rate. The instrument records the weight change as the temperature increases, producing a thermogram that reflects the material’s thermal behavior.

Benefits of TGA

- Quality Control: Ensures consistency in material composition and performance.

- Material Development: Assists in formulating materials with desired thermal properties.

- Failure Analysis: Helps identify thermal degradation issues that may lead to material failure.

With advanced equipment and experienced staff, CMG delivers accurate, reproducible TGA data tailored to your needs. Whether for quality assurance, R&D, or failure analysis, we provide actionable insights to help you optimize material performance.

Contact us today to learn more about our TGA testing services.