Tensile Testing Services (ASTM D412 and Beyond)

Tensile testing is a fundamental process for evaluating the mechanical properties of rubber and polymer materials under tension. At CMG, we specialize in providing precise tensile testing services tailored to your material performance needs.

What is Tensile Testing?

Tensile testing measures how a material responds to forces that pull it apart. This process provides key insights into properties such as tensile strength, elongation, and tensile modulus. It’s critical for understanding how materials perform under real-world conditions, including varying speeds, temperatures, and humidity levels.

Why Tensile Testing is Crucial

Tensile testing plays a vital role in product development and quality assurance across multiple industries, including automotive, aerospace, construction, and medical. Whether evaluating new materials or benchmarking legacy products, tensile testing ensures your materials meet performance expectations under their intended service conditions.

For example:

- Seals and Gaskets: These components expand and contract during normal use and must return to their original shape to function correctly. Tensile testing assesses these materials’ tensile set properties, predicting their reliability.

- Extreme Environments: Materials for engine compartments or outdoor applications must endure dramatic temperature fluctuations. By testing at multiple temperatures, we predict how performance is impacted by environmental changes.

- Aging Effects: Comparing the tensile properties of unaged and aged samples helps determine how a material’s strength and elongation change over time, offering insights into its service life.

Testing Standards We Use

We adhere to globally recognized standards to deliver reliable, actionable results:

- ASTM D412 – Tensile Properties of Vulcanized Rubber and Thermoplastic Elastomers:

- Tensile Set: Evaluates a material’s ability to return to its original dimensions after being stretched.

- Tensile Stress at Elongation: Measures the force required to stretch the material to a specific length.

- Tensile Strength: Determines the maximum stress a material can endure before breaking.

- Ultimate Elongation: Identifies the maximum elongation the material can achieve before rupture.

Testing is performed on specially prepared specimens, such as dumbbells (“dogbones”), straight sections, or rings, ensuring precise and consistent results. For materials subjected to varying conditions, tests can be conducted in temperature-controlled chambers.

- ASTM D638 – Tensile Properties of Plastics:

While ASTM D412 is ideal for rubber and thermoplastic elastomers, ASTM D638 focuses on plastics, measuring properties like tensile strength, modulus, elongation, and Poisson’s Ratio. For materials under 1mm thick, ASTM D882 is recommended.

Our Approach to Tensile Testing

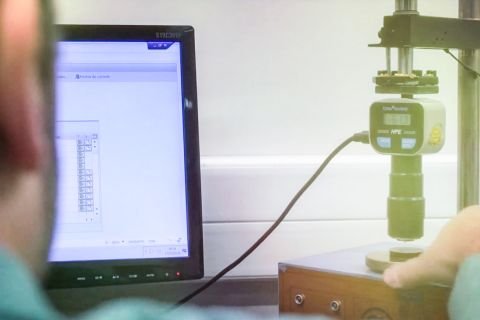

At CMG, we use state-of-the-art equipment, including universal testing machines, automated tensile testers, and extensometers, to deliver precise data. Our environmental conditioning chambers simulate real-world conditions to assess material performance under specific environmental stresses.

Our expert team ensures meticulous sample preparation, extracting specimens from new materials, finished products, or aged samples. This comprehensive approach helps you evaluate material properties, validate performance, and predict service life with confidence.

Why Choose Us?

- Comprehensive Testing: From basic tensile tests to advanced stress-strain analysis, we provide a complete suite of services.

- Experienced Team: Our experts leverage years of industry and lab experience to provide actionable insights tailored to your needs.

- Custom Solutions: We collaborate with you to address specific goals, whether it’s improving a product’s design, optimizing material selection, or benchmarking performance.