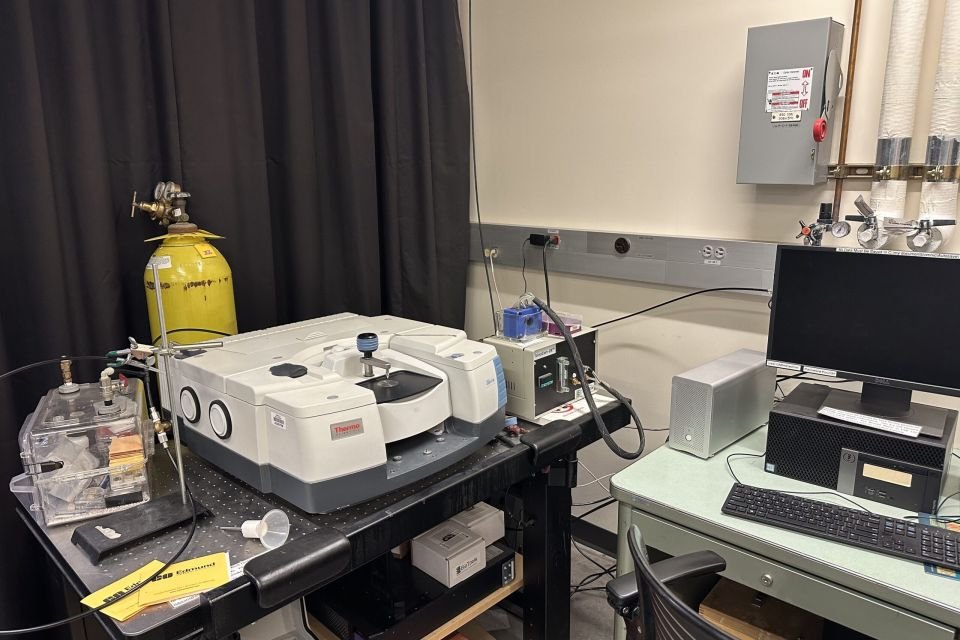

Fourier Transform Infrared (FTIR) Analysis

Fourier Transform Infrared (FTIR) spectroscopy is a powerful analytical technique used to identify the base polymer and other chemical components in rubber compounds. At CMG, we use FTIR to support material identification, quality control, and failure analysis in a variety of industries.

What is FTIR?

FTIR works by passing infrared radiation through a material and measuring its absorption at various wavelengths. This produces a unique spectral “fingerprint” of the material, enabling precise identification of its chemical structure. FTIR is particularly valuable for analyzing polymers and rubber materials because each functional group absorbs light at characteristic frequencies.

Applications of FTIR for Rubber

FTIR analysis is widely used in rubber and polymer testing to:

- Identify Polymers: Determine the base polymer in rubber compounds to verify material properties and ensure suitability for end-use applications.

- Detect Contaminants: Identify foreign particles, fibers, or additives that may impact material performance.

- Support Failure Analysis: Investigate issues such as oxidation, decomposition, or uncured monomers.

- Characterize Additives: Analyze additives such as plasticizers or stabilizers extracted from a rubber matrix.

- Competitive Benchmarking: Compare unknown materials to known standards for material evaluation.

Benefits of FTIR Analysis

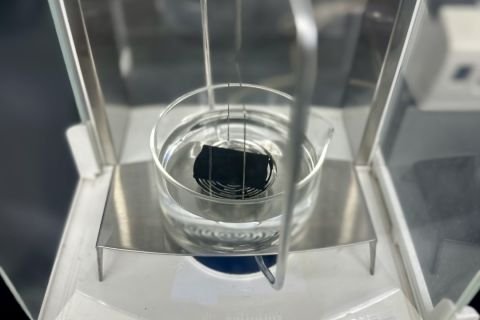

- Non-Destructive Testing: Requires minimal sample preparation and preserves the sample for additional tests.

- Rapid and Reliable Results: Provides quick, actionable insights for quality control and research purposes.

- Comprehensive Material Characterization: Identifies polymers, additives, fillers, and contaminants to provide a complete understanding of material composition.

How FTIR Works

A small sample of the material—solid, liquid, or powder—is placed in the FTIR spectrometer. Infrared radiation is passed through the sample, and the resulting spectrum reveals the material’s molecular structure. For rubber, FTIR can detect key material properties such as elasticity changes, oxidation levels, and polymer composition.

Standards and Advanced Analysis

FTIR can be paired with complementary methods such as Thermogravimetric Analysis (TGA) and Gas Chromatography (GC) for more detailed material studies.

Why Choose CMG?

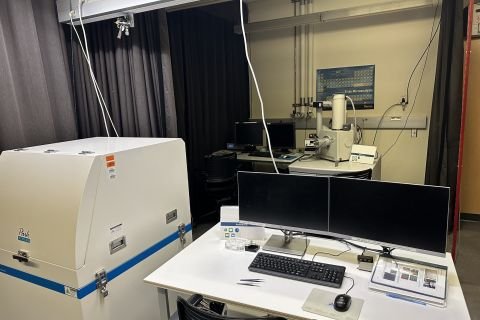

With cutting-edge FTIR instrumentation and a skilled team of analysts, we deliver accurate results tailored to your needs. Whether identifying polymers, ensuring quality control, or investigating material failures, we provide the expertise and insights you need to optimize your processes.

Contact us today to learn more about our FTIR testing services.