Chemical Analysis for Rubber Products (ASTM D297)

ASTM D297 provides standardized methods for analyzing the chemical composition of rubber, ensuring consistent quality and performance across natural and synthetic rubber products. At CMG, we specialize in precise chemical analysis to help manufacturers optimize formulations and meet industry standards.

Purpose of ASTM D297

The primary goals of ASTM D297 include:

- Quality Control: Ensuring consistent, high-quality rubber products through precise analytical techniques.

- Research & Development: Supporting innovation and improvement in rubber formulations.

- Regulatory Compliance: Meeting industry and contractual requirements for chemical composition.

Test Categories in ASTM D297

- General Tests :

These methods evaluate overall chemical composition, including:- Polymer Content: Measured indirectly (via ASTM D792).

- Extract Analysis: Identifying soluble components.

- Sulfur Content: Assessing vulcanization agents.

- Filler and Ash Content: Measuring inorganic materials.

- Density Testing: Determining the rubber’s mass-to-volume ratio.

- Specific Tests:

These methods identify specific rubber polymers in crude, unvulcanized, reclaimed, or vulcanized rubbers.

Key Test Procedures

- Polymer Identification: Determines the base polymer using solubility testing and chemical reactions.

- Ash Content Analysis: Measures inorganic filler levels by burning the sample.

- Sulfur Analysis: Evaluates sulfur content, essential for vulcanization.

- Plasticizer & Oil Content: Identifies additives through extraction and gravimetric analysis.

Applications of ASTM D297

Chemical analysis is vital across industries such as automotive, aerospace, and manufacturing to ensure the durability and performance of rubber materials.

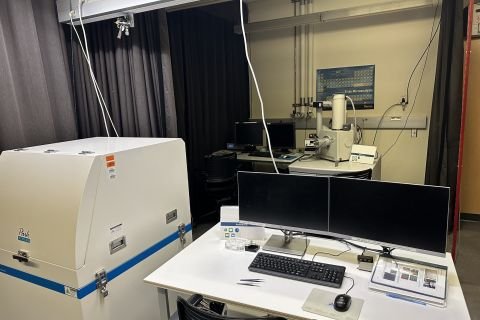

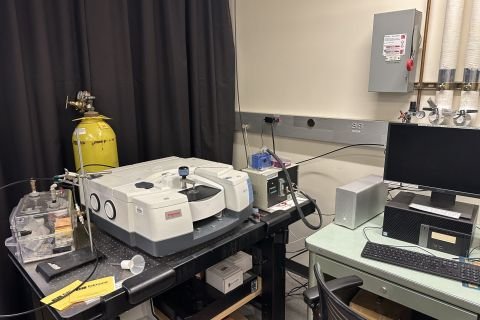

Why Choose CMG?

Our expertise and cutting-edge equipment ensure precise analysis, helping you optimize rubber formulations, ensure compliance, and achieve consistent product quality. Contact us today to learn more about our ASTM D297 testing services.